If you had toured the factory of Suwa Seikosha, Epson’s predecessor, in Japan in the 1970s, you would’ve seen long rows of workers painstakingly hand-assembling the company’s signature Seiko quartz watches. In 1981, a team of seven embarked on a project to build a flexible production system capable of more accurately and efficiently assembling tiny watch parts — and Epson’s robot business was born.

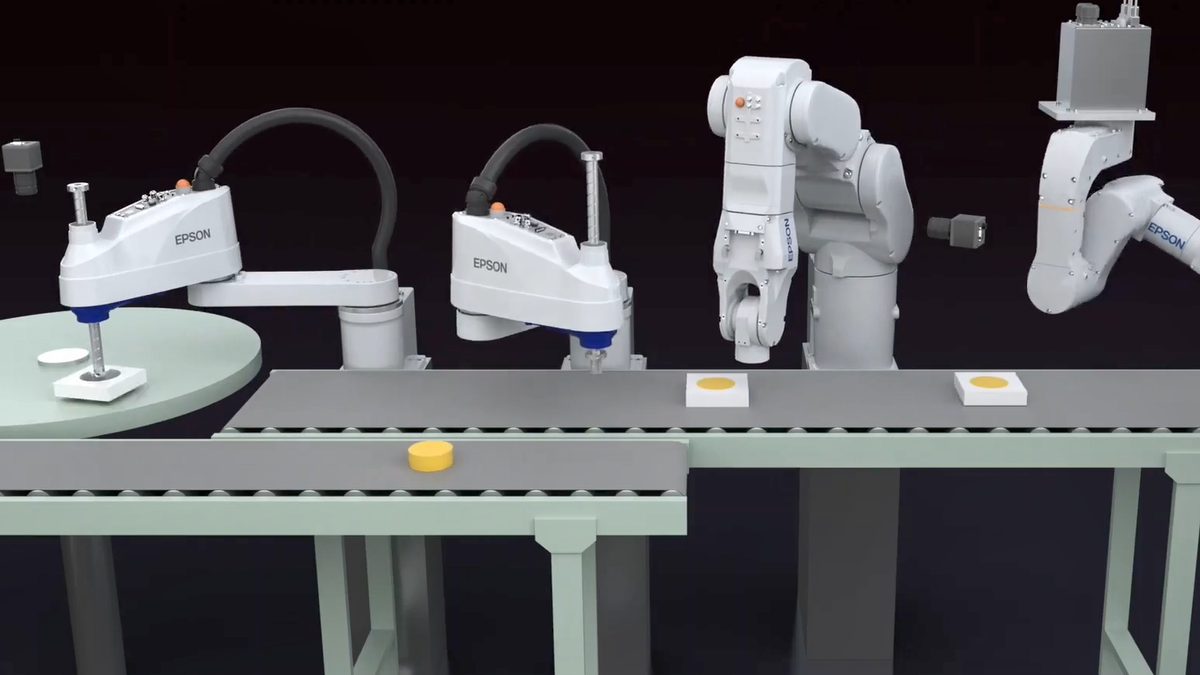

Epson produced its first SCARA robots 40 years ago, in May 1983. For this article, we asked Keijiro Naito, who heads the manufacturing solutions business, about the history of Epson’s robotics business and what the future holds for Epson as a manufacturer.

“The original product plans indicate an extraordinary level of precision,” says Keijiro Naito, head of Epson’s Manufacturing Solutions Operations Division, which produces Epson robots. The company’s first commercial line, the SSR-H series of SCARA-type precision-assembly robots released in 1983, delivered position repeatability of ±0.015 mm and a maximum operating speed of 2 meters per second.

But if precision was paramount for Epson’s first robot developers, today Naito believes there’s more to the equation. He notes that Epson’s corporate purpose statement, established last year, reads, “Our philosophy of efficient, compact, and precise innovation enriches lives and helps create a better world.” “Precision is the first requirement of a robot. The second requirement is productivity,” he observes. “A robot has to be fast to serve more customers. Precision and speed are often antagonistic, so finding solutions that enable these characteristics to exist simultaneously will remain a key focus going forward.”

It’s part of a larger evolution in Epson’s approach: looking at robots as a potential tool in developing a solution rather than the solution itself.

“Epson robots are used in our own printhead and watch manufacturing lines. To make a better robot, our habit is not to simply increase the operating speed of robots but to carefully contemplate how we can integrate them in an entire process to make them easier to use and more efficient,” says Naito. In the same way, Epson sales representatives “don’t just sell robots, they work closely with customers to explore and identify the best solutions for them. A lot of customers experience the same problems we do, so if we have well-thought-out solutions and production expertise, we can solve their problems more quickly.”

As Epson celebrates four decades of commercial robots, what does the future hold? “I believe that we need to drive innovation in a way that minimizes environmental impact,” he says. One example he offers: finding ways to consolidate the various manufacturing processes for a product in a single compact, automated assembly plant — eliminating the waste and pollution of packaging parts and transporting them from one manufacturing location to another.

Naito is also intrigued by exploring ways to answer the shift from the era of mass production to an era of mass customization. “The demand for personalized products will mean production of a far greater variety of products in batches as small as one. Could we use our 3D printing technology for this? Could we use a robot with a printhead mounted on the arm to add custom colors? I want to take on the challenge of customization and low-volume, high-mix production.”

As for the longer term, “I get the feeling that we are going to see a rapid rise in the number of sectors besides just manufacturing where there will be labor shortages,” he says. “We also want to support food preparation factories, agriculture, and other sectors where tasks are simple but currently rely on people. We don’t want robots to take people’s jobs; we want them to improve people’s lives.”

![]()