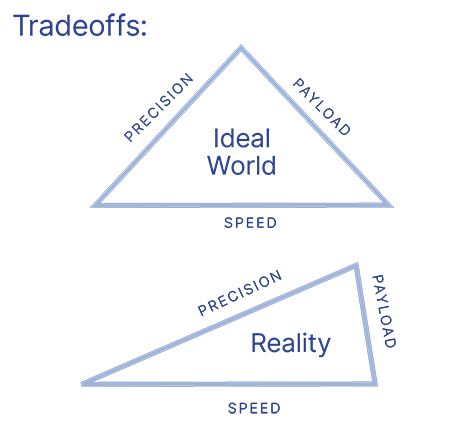

Innovations in robotic automation have allowed manufacturers in countless industries to achieve higher throughput, improved quality, and safer working environments. But choosing a robot for an automation task often involves balancing tradeoffs between three key performance criteria: speed, payload, and precision. In other words, to achieve high precision, a user may have to sacrifice somewhat on the application’s speed and payload. Alternatively, if the robot’s payload is increased, the operating speed may need to be reduced.

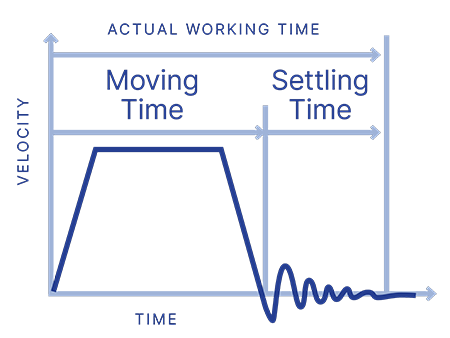

The underlying cause of these performance tradeoffs is vibration of the robot arm. Take, for example, the objective of reducing cycle time. The easiest – and in many cases, most effective – way to reduce cycle time is to increase the robot’s speed and acceleration. But high speed and acceleration can lead to vibration in the robot arm. And vibration means longer settling time and reduced precision – so much of the cycle time improvement that was gained by increasing speed and acceleration is lost waiting for the vibration to settle, or dissipate, before the next process can be performed.

Manufacturing processes increasingly demand shorter cycle times

for improved throughput, which in turn, requires higher speed and

acceleration rates from the robot. But as speed and acceleration increase,

so does vibration in the robot arm. As a result, the ratio of settling time to the

overall cycle time increases, reducing throughput and precision.

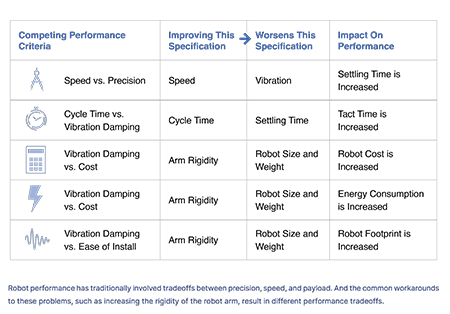

Performance tradeoffs and workarounds

Robots estimate how the end of the arm is moving – and what control commands to issue to achieve the required position and velocity – based on position and speed information from the motor encoder. But a robot arm isn’t perfectly rigid, so naturally, it experiences some amount of deflection. And the farther the end of the arm is from the motor, the higher the robot’s speed, and the heavier its payload, the more deflection the arm will experience. This means the actual speed and position values at the end of the robot arm often differ from the estimates based on the motor, and the vibration at the end of the arm goes undetected by the motor encoder. So the commands from the controller are based on inaccurate estimates of the behavior of the robot arm, compromising its ability to reach the intended position.

A common workaround to address vibration of the robot arm is to make the arm stiffer. But increasing the stiffness of the robot arm also requires increasing its weight. And a heavier robot means higher cost due to larger motors, gearboxes, and other drive components, higher energy consumption, and – typically – a larger footprint. So, even with these “workarounds” to address vibration, the user or machine builder is still faced with tradeoffs between performance and cost.

GYROPLUS Technology: A new way to address the speed-payload-precision dilemma

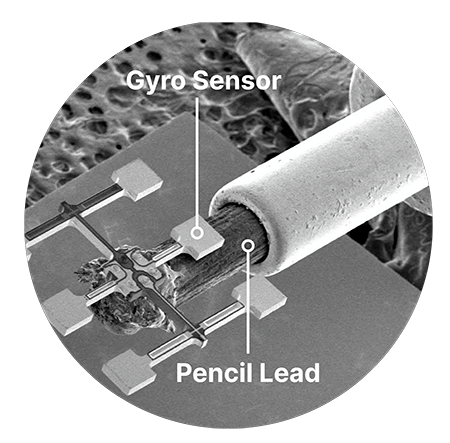

For decades, these performance tradeoffs have been accepted as an inevitable part of robot selection and operation – the laws of physics haven’t changed. But thanks to advances in gyro sensors, the compromises between a robot’s speed, payload, and precision are finally being addressed.

Gyro sensors are used extensively in applications such as vehicle navigation, but their size has – historically – made their use in robotics difficult. However, a new gyro sensor design has made it possible to integrate the sensor directly into the end of the robot arm without affecting the robot’s weight, size, or inertia.

Gyro sensors are used in devices such as automobile navigation systems,

and typical sizes are relatively large – about the size of a thumb.

But Epson’s GYROPLUS Technology uses a gyro sensor small enough

to balance on the end of a pencil lead.

Mitigating tradeoffs in robot performance

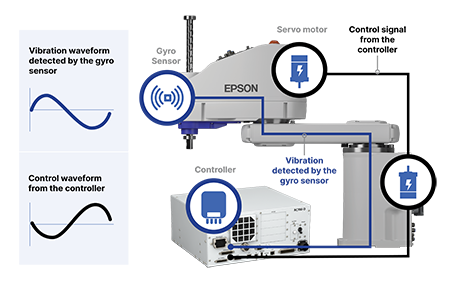

Now, with a gyro sensor mounted at the end of the robot arm, the robot controller receives information about the behavior directly at the end of the arm, so it can deliver motion commands to address the exact movement and position of the arm, rather than an estimate based on the motor’s angle and velocity. This means more precise control of positioning, along with significant vibration reduction.

Image: Robot Control Schematic

This new sensor integration, patented by Epson and referred to as GYROPLUS Technology, also means that smaller, lighter-weight robot arms can now execute faster moves, handle heavier payloads, and provide better precision than traditional robots without this technology. In other words, machine builders and end users can get higher throughput and precision from their robotic automation solutions. And with GYROPLUS Technology, SCARA and 6-Axis robots can now be used in applications that were previously inaccessible to these technologies, due to precision, payload, and cycle time requirements that were just beyond the robots’ capabilities. For example, in applications where machine builders and end users were once forced to use complex Cartesian and gantry robots for high-speed, high-precision applications, they can now use SCARA and 6-Axis robots to achieve the same or better performance, but with a much smaller footprint, less mass, simpler integration, and less complex programming.

Take a look at the complete Epson white paper, Taking Robot Performance to the Next Level, to learn more about addressing tradeoffs in robots performance with GYROPLUS advanced robots technology.

This article was originally posted by the Association for Advancing Automation and can be found at: https://www.automate.org/blogs/how-to-address-tradeoffs-in-robot-performance

![]()