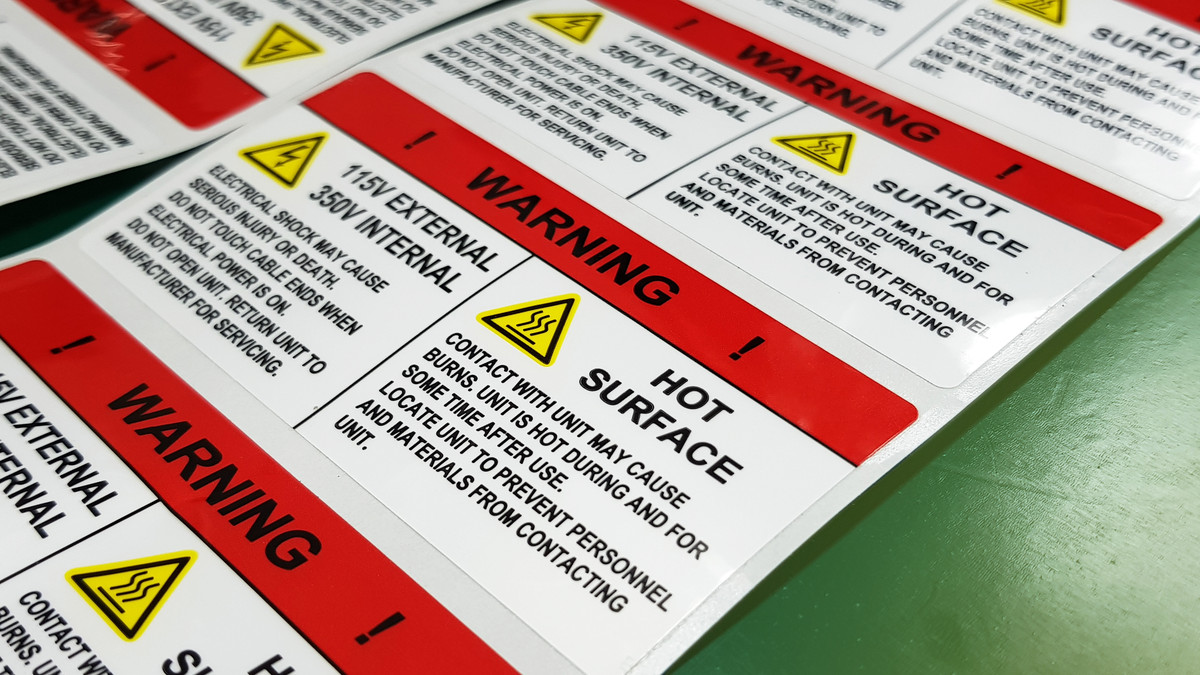

Durable labels are big business — they outnumber any other type of labels worldwide. Every industrial product, component, container, and machine requires at least one, and more often a whole set of durable labels. They come in all sizes, shapes, and appearance, each with its own uniquely challenging requirements for endurance, information, and performance.

Even so, durable labels for a given spec rarely differ from one another. Stringent regulations and industry standards require that all durable labels of a type have the same adherence, endurance, and information, symbols or images. This uniform construction makes it difficult for converters to differentiate their products.

Fortunately, certain best practices enable durable labels converters to do more for clients than simply meet their requirements. Specifically, converters can increase flexibility, specialize, and master their understanding of durable labels construction. With the right techniques, a durable label converter can become the go-to solution for clients in a wide variety of industries.

Lock in your reputation as an authority for potential clients

How can one durable label converter distinguish its products from competitors? It starts with prioritizing high performance not only in your products but also in your operations and expertise. Consider how the following techniques ensure your clients always get the best durable labels available in the market.

Make your operations flexible to meet any industry requirements

Each durable label use case already has its own special construction requirements: adhesives, inks, substrates, and others. As a converter, needs vary from client to client depending on their products and industry. It’s in your interest to build the operational capacity to serve as many of those industries as possible, even if you’re not serving some of those industries at present.

For example, there are specific rules about durable labels that enter autoclaves in biopharmaceutical production environments, and there are unique but different requirements for aftermarket auto manufacturing components. Your printer, media, and personnel must be flexible enough to provide for these and other standards to deliver high-performance labels in a variety of industries.

Become an expert in the science of durable labels construction

Meeting stringent specifications in durable labels production is a whole science in and of itself. As a converter, you need an unprecedented level of expertise to marry the right adhesives, substrates, laminates, and other elements to deliver a superior product.

That’s why it’s in your interest to become an expert on the total construction of durable labels. This expertise is especially valuable because each of the various media you need for a single job may come from a different supplier. A “teamwork” must exist between these elements, despite their separate origins.

Once these resources are secured, you need the right printing equipment to ensure consistent delivery within specifications — no matter the job or client. That means specific color matching within a very tight tolerance in industrial settings where color coding matters, or when reproducing a company logo. It also means optimized scratch or abrasion resistance through high-performing protection, such as laminates or UV varnish from a digital press.

Prioritize a press that enables you to switch between job types without causing you a lot of headaches or disruptions. As common as each type of label is to a given client, diversifying and consistent results across multiple clients and industries means better business for you.

Build a specialized inventory

The media that durable labels require are often uniform for a specific item or industry. However, materials can become segmented and even exotic as you work within different spaces. Specialized media may come at different costs with equally different performance characteristics, like 5-, 10-, or even 15-year durability, depending on industry need. Why use media with a 15-year life span for jobs that spec 5-years?

Building a specialized inventory of media ensures that you budget and stock correctly for all varieties of jobs. Adopting a label press that can handle a variety of substrates in a cost-effective way — not to mention both short and longer print runs, depending on the need — also ensures you are well equipped for any client.

To get started, have the right answers

Two of the most common questions durable labels converters receive from clients are: “What can it print on?” and “Will it survive?” It’s common for these buyers to request samples and then test their weatherability or endurance against certain environments, temperatures, and other conditions of use.

You can pass these tests with flying colors and secure new clients’ business. Specialization, flexibility, and deeper knowledge can help. A digital label press that can use a variety of media to deliver precise results — no matter the size of the print run or type of durable label — can also help you succeed.

Want to learn more? You can visit Epson.com/SurePress any time or speak directly with an Epson SurePress expert by calling:

Western U.S. (818) 620-2730 | Central U.S. (630) 710-6005 | Eastern U.S. (615) 585-9058

![]()